Thermal Conductivity of Common Materials - Solids, Liquids and Gases

Thermal conductivity of various common materials, including metals, gases, and building materials. Essential data for engineers, architects, and designers working with heat transfer and insulation.

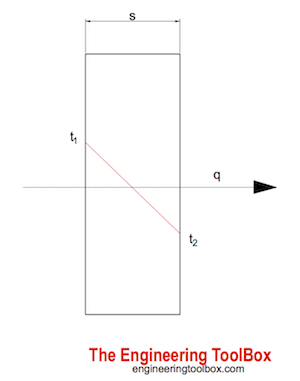

Thermal conductivity is a material property that describes ability to conduct heat . Thermal conductivity can be defined as

"the quantity of heat transmitted through a unit thickness of a material - in a direction normal to a surface of unit area - due to a unit temperature gradient under steady state conditions"

Thermal conductivity units are (W/(m K)) in the SI system and (Btu/(hr ft °F)) in the Imperial system.

See also thermal conductivity variations with temperature and pressure , for: Air, Ammonia, Carbon Dioxide and Water

Thermal conductivities for common materials and products:

| Material/Substance | Thermal Conductivity - k - W/(m K) | ||

|---|---|---|---|

| Temperature | |||

| 25 oC (77 oF) | 125 oC (257 oF) | 225 oC (437 oF) | |

| Acetals | 0.23 | ||

| Acetals | 0.23 | ||

| Acetone | 0.16 | ||

| Acetylene (gas) | 0.018 | ||

| Acrylic | 0.2 | ||

| Air, atmosphere (gas) | 0.0262 | 0.0333 | 0.0398 |

| Air, elevation 10000 m | 0.020 | ||

| Agate | 10.9 | ||

| Alcohol | 0.17 | ||

| Alumina | 36 | 26 | |

| Aluminum | |||

| Aluminum Brass | 121 | ||

| Aluminum Oxide | 30 | ||

| Ammonia (gas) | 0.0249 | 0.0369 | 0.0528 |

| Antimony | 18.5 | ||

| Apple (85.6% moisture) | 0.39 | ||

| Argon (gas) | 0.016 | ||

| Arsenic | 50 | ||

| Asbestos-cement board1) | 0.744 | ||

| Asbestos-cement sheets1) | 0.166 | ||

| Asbestos-cement1) | 2.07 | ||

| Asbestos, loosely packed1) | 0.15 | ||

| Asbestos mill board1) | 0.14 | ||

| Asphalt | 0.75 | ||

| Balsa wood | 0.048 | ||

| Barium | 18.4 | ||

| Basalt | 1.67 | ||

| Beryllium | 200 | ||

| Bismuth | 8.1 | ||

| Bitumen | 0.17 | ||

| Bitumen/felt layers | 0.5 | ||

| Beef, lean (78.9 % moisture) | 0.43 - 0.48 | ||

| Benzene | 0.16 | ||

| Beryllium | |||

| Bismuth | 8.1 | ||

| Bitumen | 0.17 | ||

| Blast furnace gas (gas) | 0.02 | ||

| Boiler scale | 1.2 - 3.5 | ||

| Boron | 25 | ||

| Brass | |||

| Breeze block | 0.10 - 0.20 | ||

| Brick dense | 1.31 | ||

| Brick, fire | 0.47 | ||

| Brick, insulating | 0.15 | ||

| Brickwork, common (Building Brick) | 0.6 -1.0 | ||

| Brickwork, dense | 1.6 | ||

| Bromine (gas) | 0.004 | ||

| Bronze | |||

| Brown iron ore | 0.58 | ||

| Butter (15% moisture content) | 0.20 | ||

| Cadmium | |||

| Calcium | 200 | ||

| Calcium silicate | 0.05 | ||

| Carbon | 1.7 | ||

| Carbon disulfide (gas) | 0.0073 | ||

| Carbon dioxide (gas) | 0.0146 | ||

| Carbon monoxide (gas) | 0.0232 | ||

| Cast iron | |||

| Cellulose, cotton, wood pulp and regenerated | 0.23 | ||

|

Cellulose acetate, molded, sheet |

0.17 - 0.33 | ||

| Cellulose nitrate, celluloid | 0.12 - 0.21 | ||

| Cement, Portland | 0.29 | ||

| Cement, mortar | 1.73 | ||

| Ceramic materials | |||

| Chalk | 0.09 | ||

| Chamotte, fireclay | 1.4 | ||

| Charcoal | 0.084 | ||

| Chlorinated poly-ether | 0.13 | ||

| Chlorine (gas) | 0.0081 | ||

| Chrome Nickel Steel (nickel-chromium steel) | 16.3 | ||

| Chromium | |||

| Chrom-oxide | 0.42 | ||

| City/town gas | 0.064 | ||

| Clay, dry to moist | 0.15 - 1.8 | ||

| Clay, saturated | 0.6 - 2.5 | ||

| Coal | 0.2 | ||

| Cobalt | |||

| Cod (83% moisture content) | 0.54 | ||

| Coke | 0.184 | ||

| Concrete, lightweight | 0.1 - 0.3 | ||

| Concrete, medium | 0.4 - 0.7 | ||

| Concrete, dense | 1.0 - 1.8 | ||

| Concrete, stone | 1.7 | ||

| Constantan | 23.3 | ||

| Copper | |||

| Corian (ceramic filled) | 1.06 | ||

| Cork board | 0.043 | ||

| Cork, re-granulated | 0.044 | ||

| Cork | 0.07 | ||

| Cotton | 0.04 | ||

| Cotton wool | 0.029 | ||

| Carbon Steel | |||

| Cotton Wool insulation | 0.029 | ||

| Cupronickel 30% | 30 | ||

| Diamond | 1000 | ||

| Diatomaceous earth (Sil-o-cel) | 0.06 | ||

| Diatomite | 0.12 | ||

| Duralium | |||

| Earth, dry | 1.5 | ||

| Ebonite | 0.17 | ||

| Emery | 11.6 | ||

| Engine Oil | 0.15 | ||

| Ethane (gas) | 0.018 | ||

| Ethanol vapor | 0.015 | ||

| Ether | 0.14 | ||

| Ethylene (gas) | 0.017 | ||

| Epoxy | 0.35 | ||

| Ethylene glycol | 0.25 | ||

| Feathers | 0.034 | ||

| Felt insulation | 0.04 | ||

| Fiberglass | 0.04 | ||

| Fiber insulating board | 0.048 | ||

| Fiber hardboard | 0.2 | ||

| Fire-clay brick 500 oC | 1.4 | ||

| Fluorine (gas) | 0.0254 | ||

| Foam glass | 0.045 | ||

| Dichlorodifluoromethane R-12 (gas) | 0.007 | ||

| Dichlorodifluoromethane R-12 (liquid) | 0.09 | ||

| Gasoline | 0.15 | ||

| Germanium | 59.9 | ||

| Glass | 1.05 | ||

| Glass, Pearls, dry | 0.18 | ||

| Glass, Pearls, saturated | 0.76 | ||

| Glass, window | 0.96 | ||

| Glass, wool Insulation | 0.04 | ||

| Glycerol | 0.28 | ||

| Gold | |||

| Granite | 1.7 - 4.0 | ||

| Graphite | 168 | ||

| Gravel | 0.7 | ||

| Ground or soil, very moist area | 1.4 | ||

| Ground or soil, moist area | 1.0 | ||

| Ground or soil, dry area | 0.5 | ||

| Ground or soil, very dry area | 0.33 | ||

| Gypsum board | 0.17 | ||

| Hairfelt | 0.05 | ||

| Hardboard high density | 0.15 | ||

| Hardwoods (oak, maple..) | 0.16 | ||

| Hastelloy C | 12 | ||

| Helium (gas) | 0.142 | ||

| Honey (12.6% moisture content) | 0.5 | ||

| Hydrochloric acid (gas) | 0.013 | ||

| Hydrogen (gas) | 0.168 | ||

| Hydrogen chloride (gas) | 0.014 | ||

| Hydrogen sulfide (gas) | 0.013 | ||

| Ice (0 oC, 32 oF) | 2.18 | ||

| Indium | 81.6 | ||

| Inconel | 15 | ||

| Ingot iron | 47 - 58 | ||

| Insulation materials | 0.035 - 0.16 | ||

| Iodine | 0.44 | ||

| Iridium | 147 | ||

| Iron | |||

| Iron-oxide | 0.58 | ||

| Kapok insulation | 0.034 | ||

| Kerosene | 0.15 | ||

| Krypton (gas) | 0.0088 | ||

| Lead | |||

| Leather, dry | 0.14 | ||

| Limestone | 1.26 - 1.33 | ||

| LInoleum | 0.19 | ||

| Lithium | |||

| Magnesia insulation (85%) | 0.07 | ||

| Magnesite | 4.15 | ||

| Magnesium | |||

| Magnesium alloy | 70 - 145 | ||

| Marble | 2.08 - 2.94 | ||

| Mercury, liquid | |||

| Methane (gas) | 0.030 | ||

| Methanol | 0.21 | ||

| Mica | 0.71 | ||

| Milk | 0.53 | ||

| Mineral wool insulation materials, wool blankets .. | 0.04 | ||

| Molybdenum | |||

| Monel | |||

| Neon (gas) | 0.046 | ||

| Neoprene | 0.05 | ||

| Niobium | 53.7 | ||

| Nickel | |||

| Nitric oxide (gas) | 0.0238 | ||

| Nitrogen (gas) | 0.024 | ||

| Nitrous oxide (gas) | 0.0151 | ||

| Nylon 6, Nylon 6/6 | 0.25 | ||

| Oil, machine lubricating SAE 50 | 0.15 | ||

| Olive oil | 0.17 | ||

| Osmium | 87.6 | ||

| Oxygen (gas) | 0.024 | ||

| Ozone (gas) | 0.019 | ||

| Palladium | 70.9 | ||

| Paper | 0.05 | ||

| Paraffin Wax | 0.25 | ||

| Peat | 0.08 | ||

| Perlite, atmospheric pressure | 0.031 | ||

| Perlite, vacuum | 0.00137 | ||

| Phenolic cast resins | 0.15 | ||

| Phenol-formaldehyde moulding compounds | 0.13 - 0.25 | ||

| Phosphorbronze | 110 | ||

| Pinchbeck | 159 | ||

| Pitch | 0.13 | ||

| Pit coal | 0.24 | ||

| Plaster light | 0.2 | ||

| Plaster, metal lath | 0.47 | ||

| Plaster, sand | 0.71 | ||

| Plaster, wood lath | 0.28 | ||

| Plasticine | 0.65 - 0.8 | ||

| Plastics, foamed (insulation materials) | 0.03 | ||

| Platinum | |||

| Plutonium | |||

| Plywood | 0.13 | ||

| Polyamid | 0.31 | ||

| Polycarbonate | 0.19 | ||

| Polyester | 0.05 | ||

| Polyethylene low density, PEL | 0.33 | ||

| Polyethylene high density, PEH | 0.42 - 0.51 | ||

| Polyisoprene natural rubber | 0.13 | ||

| Polyisoprene hard rubber | 0.16 | ||

| Polymethylmethacrylate | 0.17 - 0.25 | ||

| Polypropylene, PP | 0.1 - 0.22 | ||

| Polystyrene, expanded | 0.03 | ||

| Polystyrol | 0.043 | ||

| Polyurethane foam | 0.03 | ||

| Porcelain | 1.5 | ||

| Potassium | 102.4 | ||

| Potato, raw flesh | 0.55 | ||

| Propane (gas) | 0.015 | ||

| Propylene (gas) | 0.017 | ||

| Polytetrafluoroethylene (PTFE) | 0.25 | ||

| Polyvinylchloride, PVC | 0.19 | ||

| Pyrex glass | 1.005 | ||

| Quartz mineral | 3 | ||

| Radium | 18.6 | ||

| Radon (gas) | 0.0033 | ||

| Red metal | |||

| Rhenium | |||

| Rhodium | |||

| Rock, solid | 2 - 7 | ||

| Rock, porous volcanic (Tuff) | 0.5 - 2.5 | ||

| Rock Wool insulation | 0.045 | ||

| Roofing paper | 0.19 | ||

| Rosin | 0.32 | ||

| Rubber, cellular | 0.045 | ||

| Rubber, natural | 0.13 | ||

| Rubidium | |||

| Salmon (73% moisture content) | 0.50 | ||

| Sand, dry | 0.15 - 0.25 | ||

| Sand, moist | 0.25 - 2 | ||

| Sand, saturated | 2 - 4 | ||

| Sandstone | 1.7 | ||

| Sawdust | 0.08 | ||

| Selenium | |||

| Sheep wool | 0.039 | ||

| Silica aerogel | 0.02 | ||

| Silicon cast resin | 0.15 - 0.32 | ||

| Silicon carbide | 120 | ||

| Silicon oil | 0.1 | ||

| Silimanite | 151 | ||

| Silver | |||

| Slag wool | 0.042 | ||

| Slate | 2.01 | ||

| Snow (temp < 0 oC) | 0.05 - 0.25 | ||

| Sodium | |||

| Softwoods (fir, pine ..) | 0.12 | ||

| Soil, clay | 1.1 | ||

| Soil, with organic matter | 0.15 - 2 | ||

| Soil, saturated | 0.6 - 4 | ||

|

Solder 50-50 |

50 | ||

|

Soot |

0.07 | ||

|

Steam, saturated |

0.0184 | ||

| Steam, low pressure | 0.0188 | ||

| Steatite | 2 | ||

| Steel, Carbon | |||

| Steel, Stainless | |||

| Straw slab insulation, compressed | 0.09 | ||

| Styrofoam | 0.033 | ||

| Sulfur dioxide (gas) | 0.0086 | ||

| Sulfur, crystal | 0.2 | ||

| Sulfur hexafluoride | 0.011 | ||

| Sugars | 0.087 - 0.22 | ||

| Tantalum | |||

| Tar | 0.19 | ||

| Tellurium | 4.9 | ||

| Thorium | |||

| Timber, alder | 0.17 | ||

| Timber, ash | 0.16 | ||

| Timber, birch | 0.14 | ||

| Timber, larch | 0.12 | ||

| Timber, maple | 0.16 | ||

| Timber, oak | 0.17 | ||

| Timber, pitchpine | 0.14 | ||

| Timber, pockwood | 0.19 | ||

| Timber, red beech | 0.14 | ||

| Timber, red pine | 0.15 | ||

| Timber, white pine | 0.15 | ||

| Timber, walnut | 0.15 | ||

| Tin | |||

| Titanium | |||

| Tungsten | |||

| Uranium | |||

| Urethane foam | 0.021 | ||

| Vacuum | 0 | ||

| Vanadium | 30.7 | ||

| Vermiculite granules | 0.065 | ||

| Vinyl ester | 0.25 | ||

| Water | 0.606 | ||

| Water, vapor (steam) | 0.0267 | 0.0359 | |

| Wax | 0.084 | ||

| Wheat flour | 0.45 | ||

| White metal | 35 - 70 | ||

| Wood across the grain, white pine | 0.12 | ||

| Wood across the grain, balsa | 0.055 | ||

| Wood across the grain, yellow pine, timber | 0.147 | ||

| Wood, oak | 0.17 | ||

| Wool, felt | 0.07 | ||

| Wood wool, slab | 0.1 - 0.15 | ||

| Xenon (gas) | 0.0051 | ||

| Zinc | |||

| Zirconium | 22.7 | ||

1) Asbestos is bad for human health when the tiny abrasive fibers are inhaled into the lungs where they can damage the lung tissue. This seems to be exacerbated by cigarette smoking and the resulting diseases are mesothelioma and lung cancer.

- 1 W/(m K) = 1 W/(m oC) = 0.85984 kcal/(h m oC) = 0.5779 Btu/(ft h oF) = 0.048 Btu/(in h oF) = 6.935 (Btu in)/(ft² h °F)

- Thermal Conductivity - Unit Converter

- What is conductive heat transfer?

Example - Conductive Heat Transfer through an Aluminum Pot versus a Stainless Steel Pot

The conductive heat transfer through a pot wall can be calculated as

q = (k / s) A dT (1)

or alternatively

q / A = (k / s) dT

where

q = heat transfer (W, Btu/h)

A = surface area (m2, ft2)

q / A = heat transfer per unit area (W/m2, Btu/(h ft2))

k = thermal conductivity (W/mK, Btu/(hr ft °F))

dT = t1 - t2= temperature difference (oC, oF)

s = wall thickness (m, ft)

Conductive Heat Transfer Calculator

Note! - that the overall heat transfer through a surface is determined by the " overall heat transfer coefficient " - which in addition to conductive heat transfer - depends on

- the convective heat transfer coefficients on the inside and outside of the surfaces

- the radiant heat transfer coefficients on the inside and outside of the surfaces

Conductive Heat Transfer through an Aluminum Pot Wall with thickness 2 mm - temperature difference 80 oC

Thermal conductivity for aluminum is 215 W/(m K) (from the table above). Conductive heat transfer per unit area can be calculated as

q / A = ((215 W/(m K)) / (2×10-3 m)) (80 oC)

= 86 00000 (W/m2)

= 8600 (kW/m2)

Conductive Heat Transfer through a Stainless Steel Pot Wall with thickness 2 mm - temperature difference 80 oC

Thermal conductivity for stainless steel is 17 W/(m K) (from the table above). Conductive heat transfer per unit area can be calculated as

q / A = ((17 W/(m K)) / (2×10-3 m)) (80 oC)

= 680000 (W/m2)

= 680 (kW/m2)

Related Searches

thermal conductivity • heat transfer • material properties • insulation • engineering materials • conductivity values • metals • gases • building materials • thermal resistance • thermal insulation •