PVC Pipes - Temperature Expansion Loops

Calculate temperature expansion and contraction in PVC piping systems.

Temperature expansion and contraction in PVC piping systems can be compensated with

- expansion loops consisting of pipes and 90o elbows

- flexible bends

- bellows and rubber expansion joints

- piston type expansion joints

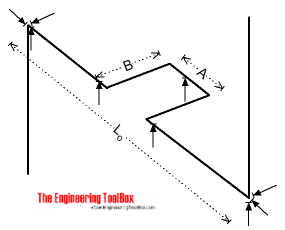

Expansion Loops

Expansion loops are made of standard pipes and elbows and can be produced on the site and adapted to the actual situation.

The length of the loop can be calculated as

Ll = ((3 E D δl) / (2 S))1/2 (1)

where

Ll = length of loop (in)

E = modulus of elasticity (psi)

D = outside diameter of pipe (in)

δl = change in pipe length L0 due to temperature change (in)

S = allowable working stress at maximum temperature (psi)

A = Ll / 5 (2)

B = 2 Ll / 5 (3)

Modulus of elasticity for PVC:

- 73 oF : 400000 psi

- 100 oF : 352000 psi

- 140 oF : 280000 psi

Modulus of elasticity for CPVC:

- 73 oF : 423000 psi

- 100 oF : 385000 psi

- 140 oF : 330000 psi

- 200 oF : 241000 psi

Maximum working stress for PVC:

- 73 oF : 2000 psi

- 100 oF : 1240 psi

- 140 oF : 440 psi

Maximum working stressfor CPVC:

- 73 oF : 2000 psi

- 100 oF : 1640 psi

- 140 oF : 1000 psi

- 200 oF : 400 psi

The temperature expansion of the pipe can be calculated as

δl = α Lo δt (4)

where

α = expansion coefficient (in/in oF)

Lo = initial length of pipe (ft)

δt = temperature change (oF)

Expansion coefficient for PVC:

- 28×10-6 in/in oF

Expansion coefficient for CPVC:

- 44×10-6 in/in oF

Example - Expansion Loop

A 2" PVC Schedule 40 straight pipe with outside diameter 2.375 inches and length 300 feet is installed at 70 oF and operated at 140 oF. The expansion coefficient for PVC is 28×10-6 in/in oF.

The expansion of the PVC pipe can from eq. 4 be calculated as

δl = α Lo δt

= (28×10-6 in/in oF) (300 ft) (12 in/ft) ((140 oF) - (70 oF))

= 7.1 inches

The modulus of elasticity is 280000 psi and the maximum working stress is 440 psi at maximum temperature. The length of the loop can from eq. 1 be calculated as

Ll = ((3 (280000 psi) (2.375 in) (7.1 in)) / (2 (440 psi)))1/2

= 126.5 in

A can be calculated from eq. 2 as

A = (126 in) / 5

= 25.3 in

B can be calculated from eq. 3 as

A = 2 (126 in) / 5

= 50.6 in