Wood, Panel and Structural Timber Products - Mechanical Properties

Density, fibre stress, compressive strength and modulus of elasticity of clear wood, panel and structural timber products.

Clear Wood

| Wood | Density - ρ - (kg/m3) | Fibre Stress at Elastic Limit - σy - (MPa) | Modulus of Elasticity - E - (GPa) | Compressive Strength parallel to Grain - σ - (MPa) | Shear Strength parallel to grain - τ - (MPa) |

|---|---|---|---|---|---|

| Alder, red | 410 | 68 | 9.5 | 40.1 | 7.4 |

| Ash - Black, Blue, Green, Oregon, White | 490 - 600 | 87 - 103 | 9.4 - 12 | 41.2 - 51.1 | 10.8 - 14 |

| Aspen - Bigtooth, Quaking | 390 | 63 | 9.9 | 36.5 | 7.4 |

| Baldcypress | 460 | 73 | 9.9 | 43.9 | 6.9 |

| Baswood, American | 370 | 60 | 10.1 | 32.6 | 6.9 |

| Beech, American | 640 | 103 | 11.9 | 50.3 | 13.9 |

| Birch - Paper, Sweet, Yellow | 550 - 620 | 85 - 114 | 11 - 15 | 39.2 - 58.9 | 8.3 - 15.4 |

| Butternut | 380 | 56 | 8.1 | 36.2 | 8.1 |

| Cedar - Atlantic White, Eastern Red, Incence, Northern White, Port-Orford, Western Red, Yellow | 310 - 470 | 45 - 88 | 5.5 - 11.7 | 27.3 - 43.5 | 5.5 - 9.4 |

| Cherry, black | 500 | 85 | 10.3 | 49 | 11.7 |

| Chestnut, American | 430 | 59 | 8.5 | 36.7 | 7.4 |

| Cottonwood - Balam Poplar, Black, Eastern | 310 - 400 | 27 - 59 | 7.6 - 9.4 | 27.7 - 33.9 | 5.4 - 7.2 |

| Douglas-fir - Coast, Inerior West, Interior North, Interior South | 460 - 500 | 82 - 90 | 10.3 - 13.4 | 43.1 - 51.2 | 7.8 - 10.4 |

| Elm, English | 560 | 40 - 54 | 11.8 | 17 - 32 | 8 - 11.3 |

| Elm, Dutch | 560 | 42 - 60 | 7.7 | 18 - 32 | 7.2 - 10 |

| Fir | 320 - 430 | 61.4 - 75.8 | 8.9 - 11.9 | 33.5 - 44.2 | 6.2 - 8.4 |

| Hackberry | 530 | 76 | 8.2 | 37.5 | 11 |

| Hemlock - Eastern, Mountain, Western | 400 - 450 | 61 - 79 | 8.3 - 11.3 | 37.3 - 49 | 7.3 - 10.6 |

| Hickory, pecan - Bitternut, Nutmeg, Pecan, Water | 600 - 660 | 94 - 123 | 11.7 - 13.9 | 47.6 - 62.3 | 14.3 |

| Hickory, true - Mockernut, Pignut, Shagbark, Shellbark | 690 - 720 | 125 - 139 | 14.9 - 15.6 | 55.2 - 63.5 | 12 - 16.8 |

| Honeylocust | 101 | 11.2 | 51.7 | 15.5 | |

| Larch, Western | 520 | 90 | 12.9 | 52.5 | |

| Locust, black | 690 | 134 | 14.1 | 70.2 | 17.1 |

| Magnolia - Cucumbertree, Southern | 480 - 500 | 77 - 85 | 9.7 - 12.5 | 37.6 - 43.5 | 9.2 - 10.5 |

| Mahogany | 545 | 60 | 8.7 | 45 | 6.0 |

| Maple - Bigleaf, Black, Red, Silver, Sugar | 480 - 630 | 61 - 109 | 7.9 - 12.6 | 36 - 54 | 11.9 - 16.1 |

| Oak, red - Black, Cherrybark, laurel, Northern Red, Pin, Scarlet, Southern Red, Water, Willow | 590 - 690 | 75 - 125 | 10.3 - 13.1 | 42 - 60.3 | 9.6 - 14.3 |

| Oak, white - Bur, Chestnut, Live, Overcup, Post, Swamp Chestnut, Swamp White, White | 640 - 880 | 71 - 127 | 7.1 - 13.7 | 41.8 - 61.4 | 10.3 - 13.8 |

| Pine - Eastern White, Jack, Loblolly, Lodgepole, Longleaf, Pitch | 350 - 590 | 59 - 100 | 8.5 - 13.7 | 33.1 - 49.2 | 6.1 - 10.4 |

| Poplar, Yellow | 420 | 70 | 10.9 | 38.2 | 8.2 |

| Sassafras | 460 | 62 | 7.7 | 32.8 | 8.5 |

| Spruce - Black, Engelmann, Red, Sitka, White, Norway | 350 - 430 | 63 - 79 | 7.9 - 11 | 37 - 44 | 6.8 - 9.2 |

| Sweetgum | 520 | 86 | 11.3 | 43.6 | 11 |

| Sycamore, American | 490 | 69 | 9.8 | 37.1 | 10.1 |

| Tupelo - Black, Water | 500 | 66 | 8.3 - 8.7 | 38.1 - 40.8 | 9.2 - 11 |

| Walnut, black | 550 | 101 | 11.6 | 52.3 | 9.4 |

| Willow, black | 390 | 54 | 7 | 28.3 | 8.6 |

- values for wood with 12% moisture content

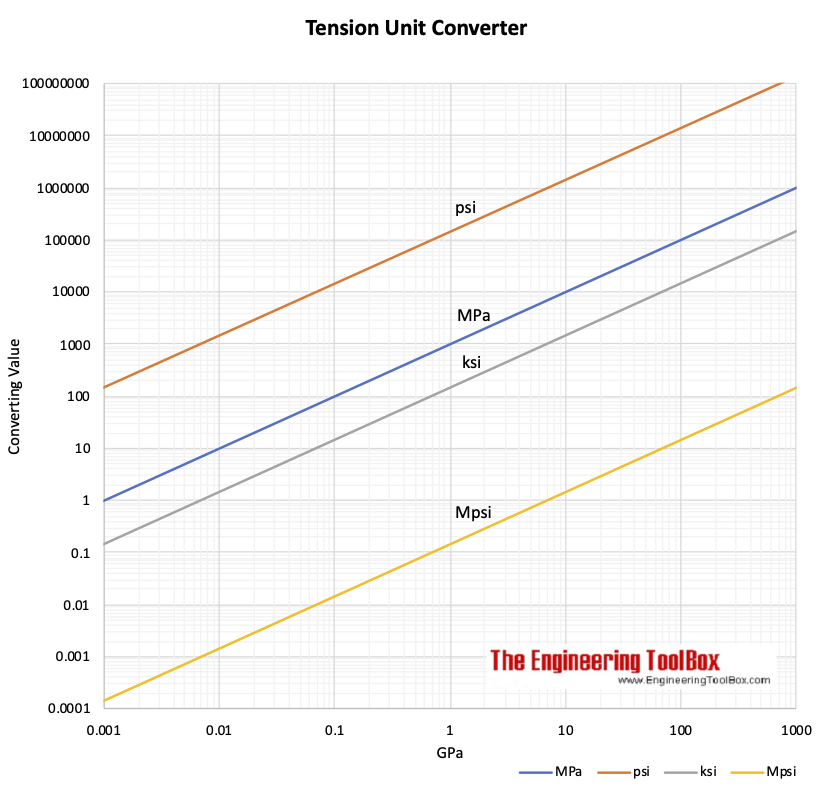

- 1 MPa = 106 Pa

- 1 GPa = 109 Pa

- Fibre Stress at Elastic Limit (Modulus of Rupture)

- Modulus of Elasticity (Tensile Modulus, Young's Modulus)

Download and print Tension Unit Converter Chart

Panel Products

| Panel | Density - ρ - (kg/m3) | Fibre Stress at Elastic Limit - σy - (MPa) | Modulus of Elasticity - E - (GPa) |

|---|---|---|---|

| Hardboard | 900 - 1000 | 31 - 56 | 3.1 - 5.5 |

| MDF - Medium Density Fiberboard | 700 - 900 | 36 | 3.6 |

| Particleboard | 600 - 800 | 15 - 24 | 2.8 - 4.1 |

| OSB - Oriented Strandboard | 500 - 800 | 22 - 35 | 4.4 - 6.3 |

| Plywood | 400 - 600 | 34 - 43 | 7 - 8.6 |

Structural Timber Products

| Structural Timber | Density - ρ - (kg/m3) | Fibre Stress at Elastic Limit - σy - (MPa) | Modulus of Elasticity - E - (GPa) |

|---|---|---|---|

| Glued-laminated Timber | 400 - 600 | 29 - 63 | 9 - 14.5 |

| Laminated Veneer Lumber | 400 - 700 | 34 - 86 | 9 - 19 |