Saturated Steam Properties – Engineering Data & Calculations, Imperial Units

Steam table with sensible, latent and total heat, and specific volume at different gauge pressures and temperatures.

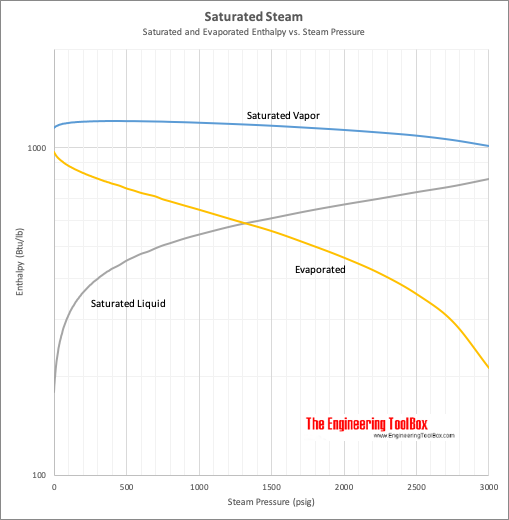

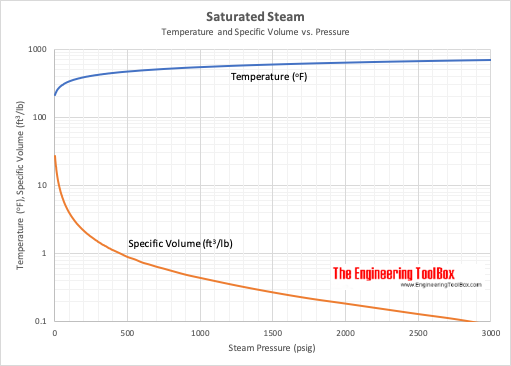

Sensible, latent and total heat in evaporated water - steam - at different gauge pressures and boiling temperatures.

| Gauge Pressure (psig) | Temperature (oF) | Specific Volume Saturated Vapor (ft3/lb) | Enthalpy | ||

|---|---|---|---|---|---|

| Saturated Liquid (Btu/lb) | Evaporated (Btu/lb) | Saturated Vapor (Btu/lb) | |||

| 25 (Inches Mercury Vacuum) |

134 | 142 | 102 | 1017 | 1119 |

| 20 (Inches Mercury Vacuum) |

162 | 73.9 | 129 | 1001 | 1130 |

| 15 (Inches Mercury Vacuum) |

179 | 51.3 | 147 | 990 | 1137 |

| 10 (Inches Mercury Vacuum) |

192 | 39.4 | 160 | 982 | 1142 |

| 5 (Inches Mercury Vacuum) |

203 | 31.8 | 171 | 976 | 1147 |

| 0 1) | 212 | 26.8 | 180 | 970 | 1150 |

| 1 | 215 | 25.2 | 183 | 968 | 1151 |

| 2 | 219 | 23.5 | 187 | 966 | 1153 |

| 3 | 222 | 22.3 | 190 | 964 | 1154 |

| 4 | 224 | 21.4 | 192 | 962 | 1154 |

| 5 | 227 | 20.1 | 195 | 960 | 1155 |

| 6 | 230 | 19.4 | 198 | 959 | 1157 |

| 7 | 232 | 18.7 | 200 | 957 | 1157 |

| 8 | 233 | 18.4 | 201 | 956 | 1157 |

| 9 | 237 | 17.1 | 205 | 954 | 1159 |

| 10 | 239 | 16.5 | 207 | 953 | 1160 |

| 12 | 244 | 15.3 | 212 | 949 | 1161 |

| 14 | 248 | 14.3 | 216 | 947 | 1163 |

| 16 | 252 | 13.4 | 220 | 944 | 1164 |

| 18 | 256 | 12.6 | 224 | 941 | 1165 |

| 20 | 259 | 11.9 | 227 | 939 | 1166 |

| 22 | 262 | 11.3 | 230 | 937 | 1167 |

| 24 | 265 | 10.8 | 233 | 934 | 1167 |

| 26 | 268 | 10.3 | 236 | 933 | 1169 |

| 28 | 271 | 9.85 | 239 | 930 | 1169 |

| 30 | 274 | 9.46 | 243 | 929 | 1172 |

| 32 | 277 | 9.1 | 246 | 927 | 1173 |

| 34 | 279 | 8.75 | 248 | 925 | 1173 |

| 36 | 282 | 8.42 | 251 | 923 | 1174 |

| 38 | 284 | 8.08 | 253 | 922 | 1175 |

| 40 | 286 | 7.82 | 256 | 920 | 1176 |

| 42 | 289 | 7.57 | 258 | 918 | 1176 |

| 44 | 291 | 7.31 | 260 | 917 | 1177 |

| 46 | 293 | 7.14 | 262 | 915 | 1177 |

| 48 | 295 | 6.94 | 264 | 914 | 1178 |

| 50 | 298 | 6.68 | 267 | 912 | 1179 |

| 55 | 300 | 6.27 | 271 | 909 | 1180 |

| 60 | 307 | 5.84 | 277 | 906 | 1183 |

| 65 | 312 | 5.49 | 282 | 901 | 1183 |

| 70 | 316 | 5.18 | 286 | 898 | 1184 |

| 75 | 320 | 4.91 | 290 | 895 | 1185 |

| 80 | 324 | 4.67 | 294 | 891 | 1185 |

| 85 | 328 | 4.44 | 298 | 889 | 1187 |

| 90 | 331 | 4.24 | 302 | 886 | 1188 |

| 95 | 335 | 4.05 | 305 | 883 | 1188 |

| 100 | 338 | 3.89 | 309 | 880 | 1189 |

| 105 | 341 | 3.74 | 312 | 878 | 1190 |

| 110 | 344 | 3.59 | 316 | 875 | 1191 |

| 115 | 347 | 3.46 | 319 | 873 | 1192 |

| 120 | 350 | 3.34 | 322 | 871 | 1193 |

| 125 | 353 | 3.23 | 325 | 868 | 1193 |

| 130 | 356 | 3.12 | 328 | 866 | 1194 |

| 135 | 358 | 3.02 | 330 | 864 | 1194 |

| 140 | 361 | 2.92 | 333 | 861 | 1194 |

| 145 | 363 | 2.84 | 336 | 859 | 1195 |

| 150 | 366 | 2.74 | 339 | 857 | 1196 |

| 155 | 368 | 2.68 | 341 | 855 | 1196 |

| 160 | 371 | 2.6 | 344 | 853 | 1197 |

| 165 | 373 | 2.54 | 346 | 851 | 1197 |

| 170 | 375 | 2.47 | 348 | 849 | 1197 |

| 175 | 377 | 2.41 | 351 | 847 | 1198 |

| 180 | 380 | 2.35 | 353 | 845 | 1198 |

| 185 | 382 | 2.29 | 355 | 843 | 1198 |

| 190 | 384 | 2.24 | 358 | 841 | 1199 |

| 195 | 386 | 2.19 | 360 | 839 | 1199 |

| 200 | 388 | 2.14 | 362 | 837 | 1199 |

| 205 | 390 | 2.09 | 364 | 836 | 1200 |

| 210 | 392 | 2.05 | 366 | 834 | 1200 |

| 215 | 394 | 2 | 368 | 832 | 1200 |

| 220 | 396 | 1.96 | 370 | 830 | 1200 |

| 225 | 397 | 1.92 | 372 | 828 | 1200 |

| 230 | 399 | 1.89 | 374 | 827 | 1201 |

| 235 | 401 | 1.85 | 376 | 825 | 1201 |

| 240 | 403 | 1.81 | 378 | 823 | 1201 |

| 245 | 404 | 1.78 | 380 | 822 | 1202 |

| 250 | 406 | 1.75 | 382 | 820 | 1202 |

| 255 | 408 | 1.72 | 383 | 819 | 1202 |

| 260 | 409 | 1.69 | 385 | 817 | 1202 |

| 265 | 411 | 1.66 | 387 | 815 | 1202 |

| 270 | 413 | 1.63 | 389 | 814 | 1203 |

| 275 | 414 | 1.6 | 391 | 812 | 1203 |

| 280 | 416 | 1.57 | 392 | 811 | 1203 |

| 285 | 417 | 1.55 | 394 | 809 | 1203 |

| 290 | 418 | 1.53 | 395 | 808 | 1203 |

| 295 | 420 | 1.49 | 397 | 806 | 1203 |

| 300 | 421 | 1.47 | 398 | 805 | 1203 |

| 305 | 423 | 1.45 | 400 | 803 | 1203 |

| 310 | 425 | 1.43 | 402 | 802 | 1204 |

| 315 | 426 | 1.41 | 404 | 800 | 1204 |

| 320 | 427 | 1.38 | 405 | 799 | 1204 |

| 325 | 429 | 1.36 | 407 | 797 | 1204 |

| 330 | 430 | 1.34 | 408 | 796 | 1204 |

| 335 | 432 | 1.33 | 410 | 794 | 1204 |

| 340 | 433 | 1.31 | 411 | 793 | 1204 |

| 345 | 434 | 1.29 | 413 | 791 | 1204 |

| 350 | 435 | 1.28 | 414 | 790 | 1204 |

| 355 | 437 | 1.26 | 416 | 789 | 1205 |

| 360 | 438 | 1.24 | 417 | 788 | 1205 |

| 365 | 440 | 1.22 | 419 | 786 | 1205 |

| 370 | 441 | 1.2 | 420 | 785 | 1205 |

| 375 | 442 | 1.19 | 421 | 784 | 1205 |

| 380 | 443 | 1.18 | 422 | 783 | 1205 |

| 385 | 445 | 1.16 | 424 | 781 | 1205 |

| 390 | 446 | 1.14 | 425 | 780 | 1205 |

| 395 | 447 | 1.13 | 427 | 778 | 1205 |

| 400 | 448 | 1.12 | 428 | 777 | 1205 |

| 450 | 460 | 1 | 439 | 766 | 1205 |

| 500 | 470 | 0.89 | 453 | 751 | 1204 |

| 550 | 479 | 0.82 | 464 | 740 | 1204 |

| 600 | 489 | 0.74 | 475 | 728 | 1203 |

| 650 | 497 | 0.69 | 483 | 719 | 1202 |

| 700 | 505 | 0.64 | 491 | 710 | 1201 |

| 750 | 513 | 0.6 | 504 | 696 | 1200 |

| 800 | 520 | 0.56 | 512 | 686 | 1198 |

| 900 | 534 | 0.49 | 529 | 666 | 1195 |

| 1000 | 546 | 0.44 | 544 | 647 | 1191 |

| 1250 | 574 | 0.34 | 580 | 600 | 1180 |

| 1500 | 597 | 0.27 | 610 | 557 | 1167 |

| 1750 | 618 | 0.22 | 642 | 509 | 1151 |

| 2000 | 636 | 0.19 | 672 | 462 | 1134 |

| 2250 | 654 | 0.16 | 701 | 413 | 1114 |

| 2500 | 669 | 0.13 | 733 | 358 | 1091 |

| 2750 | 683 | 0.11 | 764 | 295 | 1059 |

| 3000 | 696 | 0.08 | 804 | 213 | 1017 |

| 3206.22) | 705.40 | - | - | - | - |

1) Atmospheric pressure is used for the table except for 2)

2) Critical Point - At 3206.2 psia and 705.40 oF the vapor and liquid are indistinguishable. No change of state occurs when pressure increases above the critical point or when heat is added. At the critical point it is no longer referred to water or steam and it is not possible keep the water and steam apart.

- 1 psi (lbf/in2) = 6894.8 Pa (N/m2) = 0.06895 bar

Note! Gauge Pressure = Absolute Pressure - Atmospheric Pressure

NTP - Normal Temperature and Pressure - is defined as 20 oC (293.15 K, 68 oF) and 1 atm ( 101.325 kN/m2, 101.325 kPa, 14.7 psia, 0 psig, 30 in Hg, 760 torr)

- Vacuum steam is the general term used for saturated steam at temperatures below 100°C.

Example - Boiling Water at 212 oF and 0 psig

At atmospheric pressure - 0 psig - water boils at 212 oF. 180 Btu/lb of energy is required to heat 1 lb of water to saturation temperature 212 oF.

Therefore, at 0 psig and 212 oF - the specific enthalpy of water is 180 Btu/lb.

Another 970 Btu/lb of energy is required to evaporate the 1 lb of water at 212 oF to steam at 212 oF. Therefore, at 0 psig - the specific enthalpy of evaporation is 970 Btu/lb.

The total specific enthalpy of the steam (or heat required to evaporate water to steam) at atmospheric pressure and 212 oF can be summarized to

hs = (180 Btu/lb) + ( 970 Btu/lb)

= 1150 Btu/lb