Metals and Alloys - Young's Modulus of Elasticity

Elastic properties and Young's modulus for metals and alloys like cast iron, carbon steel and more.

It is convenient to express the elasticity of a material with the ratio stress to strain, a parameter also termed as the tensile elastic modulus or Young's modulus of the material - usually with the symbol - E.

- Young's modulus can be used to predict the elongation or compression of an object.

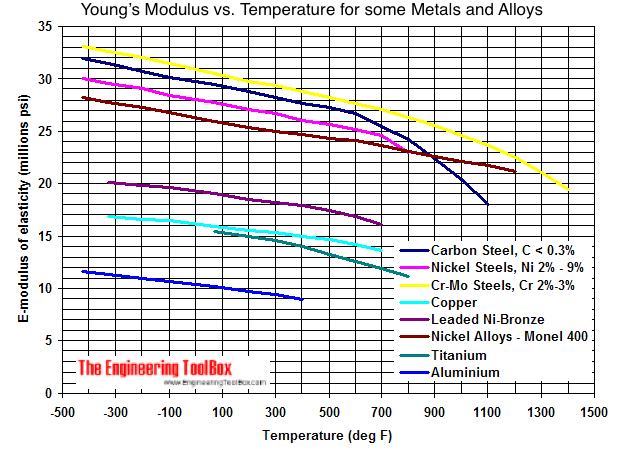

Modulus of Elasticity for some common metals at various temperatures according ASME B31.1-1995:

- 1 psi (lb/in2) = 1 psi (lb/in2) = 144 psf (lbf/ft2) = 6,894.8 Pa (N/m2) = 6.895×10-3 N/mm2

- T (oC) = 5/9 (T (oF) - 32)

For full table with Higher Temperatures - rotate the screen!

| Metal | Young's Modulus of Elasticity - E - (106 psi) | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Temperature (oC) | |||||||||||||||

| -200 | -129 | -73 | 21 | 93 | 149 | 204 | 260 | 316 | 371 | 427 | 482 | 538 | 593 | 649 | |

| Temperature (oF) | |||||||||||||||

| -325 | -200 | -100 | 70 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 | 1100 | 1200 | |

| Cast iron | |||||||||||||||

| Gray cast iron | 13.4 | 13.2 | 12.9 | 12.6 | 12.2 | 11.7 | 11.0 | 10.2 | |||||||

| Steel | |||||||||||||||

| Carbon steel C <= 0.3% | 31.4 | 30.8 | 30.2 | 29.5 | 28.8 | 28.3 | 27.7 | 27.3 | 26.7 | 25.5 | 24.2 | 22.4 | 20.4 | 18.0 | |

| Carbon steel C => 0.3% | 31.2 | 30.6 | 30.0 | 29.3 | 28.6 | 28.1 | 27.5 | 27.1 | 26.5 | 25.3 | 24.0 | 22.2 | 20.2 | 17.9 | 15.4 |

| Carbon-molybdenum steels | 31.1 | 30.5 | 29.9 | 29.2 | 28.5 | 28.0 | 27.4 | 27.0 | 26.4 | 25.3 | 23.9 | 22.2 | 20.1 | 17.8 | 15.3 |

| Nickel steels Ni 2% - 9% | 29.6 | 29.1 | 28.5 | 27.8 | 27.1 | 26.7 | 26.1 | 25.7 | 25.2 | 24.6 | 23.0 | ||||

| Cr-Mo steels Cr 1/2% - 2% | 31.6 | 31.0 | 30.4 | 29.7 | 29.0 | 28.5 | 27.9 | 27.5 | 26.9 | 26.3 | 25.5 | 24.8 | 23.9 | 23.0 | 21.8 |

| Cr-Mo steels Cr 2 1/4% - 3% | 32.6 | 32.0 | 31.4 | 30.6 | 29.8 | 29.4 | 28.8 | 28.3 | 27.7 | 27.1 | 26.3 | 25.6 | 24.6 | 23.7 | 22.5 |

| Cr-Mo steels Cr 5% - 9% | 32.9 | 32.3 | 31.7 | 30.9 | 30.1 | 29.7 | 29.0 | 28.6 | 28.0 | 27.3 | 26.1 | 24.7 | 22.7 | 20.4 | 18.2 |

| Chromium steels Cr 12%, 17%, 27% | 31.2 | 30.7 | 30.1 | 29.2 | 28.5 | 27.9 | 27.3 | 26.7 | 26.1 | 25.6 | 24.7 | 23.2 | 21.5 | 19.1 | 16.6 |

| Austenitic steels (TP304, 310, 316, 321, 347) | 30.3 | 29.7 | 29.1 | 28.3 | 27.6 | 27.0 | 26.5 | 25.8 | 25.3 | 24.8 | 24.1 | 23.5 | 22.8 | 22.1 | 21.2 |

| Copper and copper alloys | |||||||||||||||

| Comp. and leaded-Sn bronze (C83600, C92200) | 14.8 | 14.6 | 14.4 | 14.0 | 13.7 | 13.4 | 13.2 | 12.9 | 12.5 | 12.0 | |||||

| Naval brass Si & Al bronze (C46400, C65500, C95200, C95400) | 15.9 | 15.6 | 15.4 | 15.0 | 14.6 | 14.4 | 14.1 | 13.8 | 13.4 | 12.8 | |||||

| Copper (C11000) | 16.9 | 16.6 | 16.5 | 16.0 | 15.6 | 15.4 | 15.0 | 14.7 | 14.2 | 13.7 | |||||

| Copper red brass Al-bronze (C10200, C12000, C12200, C12500, C14200, C23000, C61400) | 18.0 | 17.7 | 17.5 | 17.0 | 16.6 | 16.3 | 16.0 | 15.6 | 15.1 | 14.5 | |||||

| Nickel and Nickel Alloys | |||||||||||||||

| Monel 400 (N04400) | 27.8 | 27.3 | 26.8 | 26.0 | 25.4 | 25.0 | 24.7 | 24.3 | 24.1 | 23.7 | 23.1 | 22.6 | 22.1 | 21.7 | 21.2 |

| Titanium | |||||||||||||||

| Unalloyed titanium grades 1, 2, 3 and 7 | 15.5 | 15.0 | 14.6 | 14.0 | 13.3 | 12.6 | 11.9 | 11.2 | |||||||

| Aluminum and aluminum alloys | |||||||||||||||

| Grades 443, 1060, 1100, 3003, 3004, 6063 | 11.1 | 10.8 | 10.5 | 10.0 | 9.6 | 9.2 | 8.7 | ||||||||

- 1 psi (lb/in2) = 6,894.8 N/m2 (Pa)

- T (oC) = 5/9 (T (oF) - 32)

Note! You can use the pressure unit converter to switch between units of Modulus of Elasticity.