Poisson's Ratio – Definition, Values for Materials, and Applications

Poisson's ratio, a key material property describing the relationship between axial and lateral strain in solid materials. Typical Poisson's ratio values for metals, polymers, ceramics, and more, along with practical applications in engineering and mechanics.

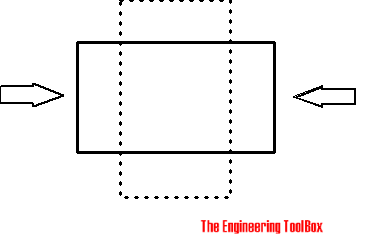

When a sample of material is stretched in one direction it tends to get thinner in the lateral direction - and if a sample is compressed in one direction it tends to get thicker in the lateral direction.

Poisson's ratio is

- the ratio of the relative contraction strain (transverse, lateral or radial strain) normal to the applied load - to the relative extension strain (or axial strain) in the direction of the applied load

Poisson's Ratio can be expressed as

μ = - εt / εl (1)

where

μ = Poisson's ratio

εt = transverse strain (m/m, ft/ft)

εl = longitudinal or axial strain (m/m, ft/ft)

Strain is defined as "deformation of a solid due to stress".

Longitudinal (or axial) strain can be expressed as

εl = dl / L (2)

where

εl = longitudinal or axial strain (dimensionless - or m/m, ft/ft)

dl = change in length (m, ft)

L = initial length (m, ft)

Contraction (or transverse, lateral or radial) strain can be expressed as

εt = dr / r (3)

where

εt = transverse, lateral or radial strain (dimensionless - or m/m, ft/ft)

dr = change in radius (m, ft)

r = initial radius (m, ft)

Eq. 1, 2 and 3 can be combined to

μ = - ( dr / r) / ( dl / L) (4)

Example - Stretching Aluminum

An aluminum bar with length 10 m and radius 100 mm (100×10-3 m) is stretched 5 mm (5×10-3 m) . The radial contraction in lateral direction can be rearranged to

dr = - μ ⋅ r ⋅ dl / L (5)

With Poisson's ratio for aluminum 0.334 - the contraction can be calculated as

dr = - 0.334 ⋅ ( 100 ⋅ 10-3 m) ( 5 ⋅ 10-3 m) / (10 m)

= 1.7 10-5 m

= 0.017 mm

Poisson's Ratios for Common Materials

For most common materials the Poisson's ratio is in the range 0 - 0.5. Typical Poisson's Ratios for some common materials are indicated below.

| Material | Poisson's Ratio - μ - |

|---|---|

| Upper limit | 0.5 |

| Aluminum | 0.334 |

| Aluminum, 6061-T6 | 0.35 |

| Aluminum, 2024-T4 | 0.32 |

| Beryllium Copper | 0.285 |

| Brass, 70-30 | 0.331 |

| Brass, cast | 0.357 |

| Bronze | 0.34 |

| Clay | 0.41 |

| Concrete | 0.1 - 0.2 |

| Copper | 0.355 |

| Cork | 0 |

| Glass, Soda | 0.22 |

| Glass, Float | 0.2 - 0.27 |

| Granite | 0.2 - 0.3 |

| Ice | 0.33 |

| Inconel | 0.27 - 0.38 |

| Iron, Cast - gray | 0.211 |

| Iron, Cast | 0.22 - 0.30 |

| Iron, Ductile | 0.26 - 0.31 |

| Iron, Malleable | 0.271 |

| Lead | 0.431 |

| Limestone | 0.2 - 0.3 |

| Magnesium | 0.35 |

| Magnesium Alloy | 0.281 |

| Marble | 0.2 - 0.3 |

| Molybdenum | 0.307 |

| Monel metal | 0.315 |

| Nickel Silver | 0.322 |

| Nickel Steel | 0.291 |

| Polystyrene | 0.34 |

| Phosphor Bronze | 0.359 |

| Rubber | 0.48 - ~0.5 |

| Sand | 0.29 |

| Sandy loam | 0.31 |

| Sandy clay | 0.37 |

| Stainless Steel 18-8 | 0.305 |

| Steel, cast | 0.265 |

| Steel, Cold-rolled | 0.287 |

| Steel, high carbon | 0.295 |

| Steel, mild | 0.303 |

| Titanium (99.0 Ti) | 0.32 |

| Wrought iron | 0.278 |

| Z-nickel | 0.36 |

| Zinc | 0.331 |

Related Searches

Poisson's ratio • material properties • elasticity • strain • engineering mechanics • axial strain • lateral strain • modulus of elasticity • structural analysis • solid mechanics •