Stress in Thin-Walled Cylinders or Tubes

Hoop and longitudinal stress thin-walled tubes or cylinders.

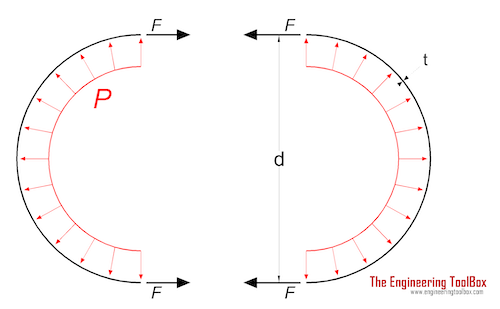

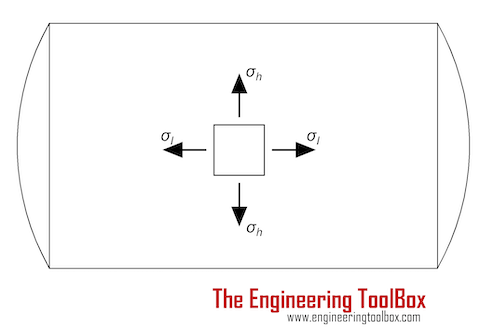

When a thin-walled tube or cylinder is subjected to internal pressure a hoop and longitudinal stress are produced in the wall.

For the thin walled equations below the wall thickness is less than 1/20 of tube or cylinder diameter.

Hoop (Circumferential) Stress

The hoop stress is acting circumferential and perpendicular to the axis and the radius of the cylinder wall. The hoop stress can be calculated as

σh = p d / (2 t) (1)

where

σh = hoop stress (MPa, psi)

p = internal pressure in the tube or cylinder (MPa, psi)

d = internal diameter of tube or cylinder (mm, in)

t = tube or cylinder wall thickness (mm, in)

Longitudinal (Axial) Stress

For a cylinder closed closed in both ends the internal pressure creates a force along the axis of the cylinder. The longitudinal stress caused by this force can be calculated as

σl = p d / (4 t) (2)

where

σl = longitudinal stress (MPa, psi)

Example - Stress in a Thin Walled Tube

The pressure in a thin walled tube with diameter 0.3 m and thickness 0.001 m is 1000 kPa (10 bar).

The hoop stress can be calculated

σh = (1000 kPa) (0.3 m) / (2 (0.001 m))

= 150000 kPa

= 150 MPa

The longitudinal stress can be calculated

σh = (1000 kPa) (0.3 m) / (4 (0.001 m))

= 75000 kPa

= 75 MPa

Note that typical maximum allowable stress for carbon steel pipes is below 135 MPa.