Belts - Pulley Diameters vs. Speed

The pulley laws - driver and driven - diameter and rpm

Pulleys - Speed vs. Pulley Diameters

| Pulley | Diameter (mm, in) | Speed (rpm) |

|---|---|---|

| 1 | ||

| 2 | ||

| 3 | ||

| 4 | ||

Single Belt Transmission - one driving pulley and one driven pulley

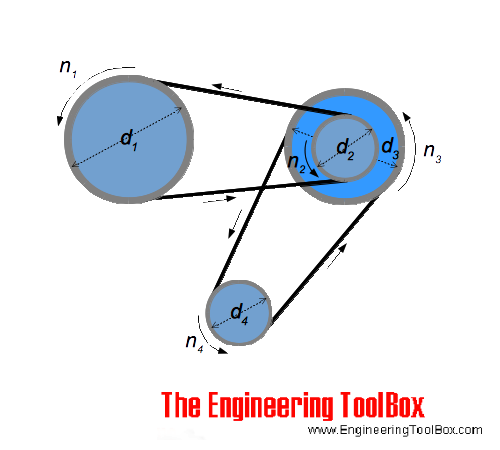

For a system with two shafts and two pulleys - as indicated with pulley 1 and 2 in the figure above:

d1 n1= d2 n2 (1)

where

d1 = driving pulley diameter (inch, mm)

n1 = revolutions of driving pulley (rpm - rounds per minute)

d2 = driven pulley diameter (inch, mm)

n2 = revolutions of driven pulley (rpm - rounds per minute)

Equation (1) can be transformed to express the

Revolution of Driven Pulley

n2 = d1 n1 / d2 (2)

Revolution of Driver Pulley

n1 = d2 n2 / d1 (3)

Diameter of Driven Pulley

d2 = d1 n1 / n2 (4)

Diameter of Driver Pulley

d1 = d2 n2 / n1 (5)

Multiple Belt Transmission Systems

For a system a with three shafts and four pulleys - as indicated in the figure above:

n2 = n3 (6)

n4 = n1 (d1 d3) / (d2 d4) (7)

Example - Multiple Belt Transmission System

The revolutions of shaft 4 in a multiple belt transmission like indicated in the figure above where

n1 = 1000 rpm

d1 = 100 mm

d2 = 50 mm

d3 = 110 mm

d4 = 60 mm

can be calculated as

n4 =(1000 rpm) (100 mm) (110 mm) / ((50 mm) (60 mm))

= 3667 rpm