Gear Trains - Bicycle Gearing Calculator

Gear train transmissions - bicycle gearing.

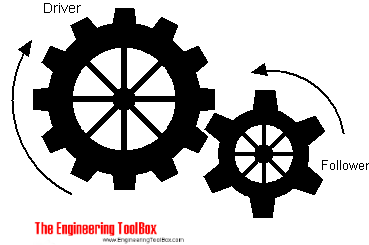

A simple gear can change magnitude and line of action of an effort force.

The effort force is applied to the "driver" and the load is applied to the "follower" .

Transmission - or Movement - Ratio

Transmission - or movement - ratio can be expressed as

iM = nD / nF

= tF / tD (1)

where

iM = movement ratio

nD = revolutions of driver (rpm)

nF = revolutions of follower (rpm)

tF = number of teeth on follower

tD = number of teeth on driver

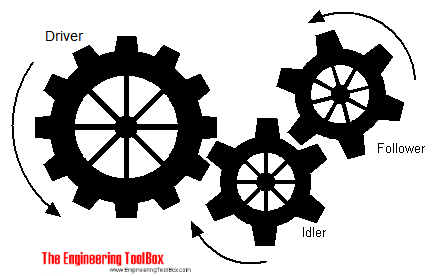

When the same direction of rotation is required for the driver and the follower, an idler wheel is used.

Gear Calculator

Calculate follower revolutions.

The movement ratio for a gear with an idler wheel can be expressed as

iM = nD / nF

= (tI / tD ) (tF / tI )

= tF / tD (1b)

where

tI = number of teeth on idler

Moment Ratio

The moment - or torque - ratio for a transmission can be expressed as

iT = MF / ML

= 1 / (iM μ) (2)

where

iT = moment ratio

μ = transmission efficiency

ML = output moment of load from follower (Nm, lb ft)

MF = input moment of force on driver (Nm, lb ft)

Transmission - Moment Ratio Calculator

Calculate follower output moment load.

The calculator is generic and can be used for SI and Imperial units - output units equals input units.

Make 3D models of spurs and gears with the Engineering ToolBox SketchUp plugin

Spurs and Gears - Use the awesome SketchUp to make 3D models of spurs and gears

Spurs and Gears - Use the awesome SketchUp to make 3D models of spurs and gears

Typical Gear Ratios

Typical gear ratios for different types of gear sets are indicated below.

| Type of Gear set | Typical Gear Ratios | |

|---|---|---|

| Min | Max | |

| Spur gear, external | 1 : 1 | 5 : 1 |

| Spur gear, internal | 1.5 : 1 | 7 : 1 |

| Helical gear, external | 1 : 1 | 10 : 1 |

| Helical gear, internal | 1.5 : 1 | 10 : 1 |

| Straight bevel gear | 1 : 1 | 8 : 1 |

| Spiral bevel gear | 1 : 1 | 8 : 1 |

| Epicyclic planetary gear | 3 : 1 | 12 : 1 |

| Epicyclic star gear | 2 : 1 | 11 : 1 |

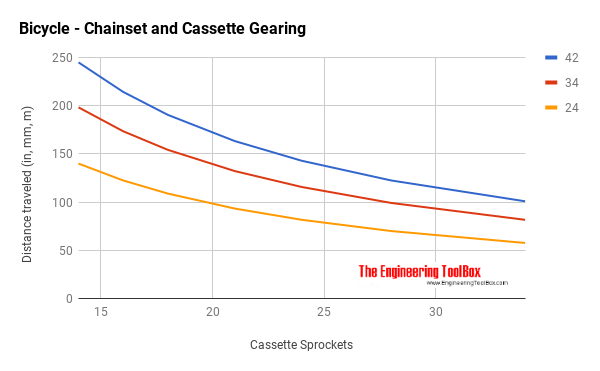

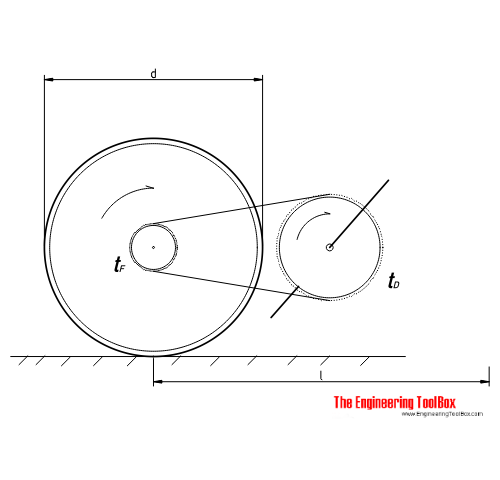

Bicycle Gearing

The revolutions of a bicycle wheel when pedaling can be calculated by transforming (2) :

nF = nD tD / tF (3)

where

nF = revolutions of the bicycle wheel (rpm)

nD = revolutions of the pedaling (rpm)

tD = number of teeth in the pedaling sprocket

tF = number of teeth in wheel sprocket

The distance traveled by the wheel can be calculated by multiplying wheel revolutions with wheel circumference:

l = c nF

= c nD tD / tF

= π d nD tD / tF (3b)

where

l = outer wheel traveled length or distance (m, in)

c = outer wheel circumference (m, in)

d = outer wheel diameter (m, in)

Example - Bicycle Gear

A mountain bike with 26 inch outer diameter wheels has a 42/34/24T chain-set and a 7-speed 14-34 cassette in the rear wheel.

The outer circumference of the wheel can be calculated as

c = π (26 in)

= 81.7 in

The distance traveled by the wheel in the lowest gear - for one pedaling revolution - using the smallest sprocket in the chainset (24T) and the largest sprocket in the cassette (34T) - can be calculated using (3b) as

l = (1) (81.6 in) (24) / (34)

= 57.7 in

The distance traveled by the wheel in the highest gear - for one pedaling revolution - using the largest sprocket in the chainset (42T) and the smallest sprocket in the cassette (14T) - can be calculated as

l = (1) (81.6 in) (42) / (14)

= 244.8 in

Bicycle Gearing Calculator

Calculate distance traveled by wheel.

The calculator is generic and can be used for SI and Imperial units - output units equals input units.

Bicycle Gearing Calculator - Template

Make your own graphical Bicycle Gearing Calculator by using this Google Docs template!