Metric Bolt Strength: Minimum, Ultimate Tensile & Proof Loads - Metric

Minimum ultimate tensile and proof loads for metric bolts with coarse or fine threads.

Metric Bolts - Coarse Threads

Minimum Ultimate Tensile Load

For full table with more Property Classes - rotate the screen!

| Thread d (mm) | Pitch P (mm) | Nominal Stress Area As,nom (mm2) | Property Class | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 4.6 | 4.8 | 5.6 | 5.8 | 6.8 | 8.8 | 9.8 | 10.9 | 12.9 | |||

| Minimum Ultimate Tensile Load - Fm,min (N) | |||||||||||

| M3 | 0.50 | 5.03 | 2010 | 2110 | 2510 | 2620 | 3020 | 4020 | 4530 | 5230 | 6140 |

| M3.5 | 0.60 | 6.78 | 2710 | 2850 | 3390 | 3530 | 4070 | 5420 | 6100 | 7050 | 8270 |

| M4 | 0.70 | 8.78 | 3510 | 3690 | 4390 | 4570 | 5270 | 7020 | 7900 | 9130 | 10700 |

| M5 | 0.80 | 14.2 | 5680 | 5960 | 7100 | 7380 | 8520 | 11350 | 12800 | 14800 | 17300 |

| M6 | 1.00 | 20.1 | 8040 | 8440 | 10000 | 10400 | 12100 | 16100 | 18100 | 20900 | 24500 |

| M7 | 1.00 | 28.9 | 11600 | 12100 | 14400 | 15000 | 17300 | 23100 | 26000 | 30100 | 35300 |

| M8 | 1.25 | 36.6 | 14600 | 15400 | 18300 | 19000 | 22000 | 29200 | 32900 | 38100 | 44600 |

| M10 | 1.50 | 58.0 | 23200 | 24400 | 29000 | 30200 | 34800 | 46400 | 52200 | 60300 | 70800 |

| M12 | 1.75 | 84.3 | 33700 | 35400 | 42200 | 43800 | 50600 | 67400d) | 75200 | 87700 | 103000 |

| M14 | 2.00 | 115 | 46000 | 48300 | 57500 | 59800 | 69000 | 92000d) | 104000 | 120000 | 140000 |

| M16 | 2.00 | 157 | 62800 | 65900 | 78500 | 81600 | 94000 | 125000d) | 141000 | 163000 | 192000 |

| M18 | 2.50 | 192 | 76800 | 80600 | 96000 | 99800 | 115000 | 159000 | 200000 | 234000 | |

| M20 | 2.50 | 245 | 98000 | 103000 | 122000 | 127000 | 147000 | 203000 | 250000 | 299000 | |

| M22 | 2.50 | 303 | 121000 | 127000 | 152000 | 158000 | 182000 | 252000 | 315000 | 370000 | |

| M24 | 3.00 | 353 | 141000 | 148000 | 176000 | 184000 | 212000 | 293000 | 367000 | 431000 | |

| M27 | 3.00 | 459 | 184000 | 193000 | 230000 | 239000 | 275000 | 381000 | 477000 | 560000 | |

| M30 | 3.50 | 561 | 224000 | 236000 | 280000 | 292000 | 337000 | 466000 | 583000 | 684000 | |

| M33 | 3.50 | 694 | 278000 | 292000 | 347000 | 361000 | 416000 | 576000 | 722000 | 847000 | |

| M36 | 4.00 | 817 | 327000 | 343000 | 408000 | 425000 | 490000 | 678000 | 850000 | 997000 | |

| M39 | 4.00 | 976 | 390000 | 410000 | 488000 | 508000 | 586000 | 810000 | 1020000 | 1200000 | |

d) For structural bolting: 70000 N (M12), 95500 N (M14) and 130000 N (M16)

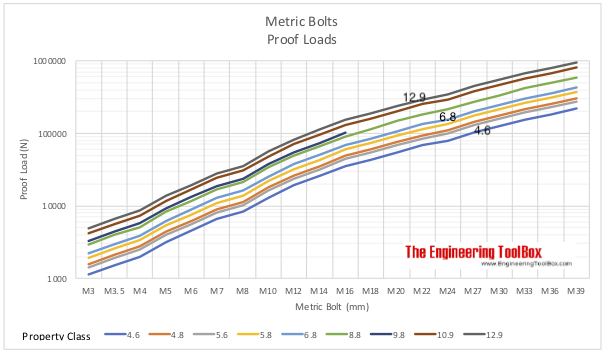

Proof Load

Proof load is defined as the maximum tensile force that can be applied to a bolt that will not result in plastic deformation. A material must remain in its elastic region when loaded up to its proof load typically between 85-95% of the yield strength. Acceptable clamp load is typically 75% of proof load.

For full table with more Property Classes - rotate the screen!

| Thread d (mm) | Pitch P (mm) | Nominal Stress Area As,nom (mm2) | Property Class | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 4.6 | 4.8 | 5.6 | 5.8 | 6.8 | 8.8 | 9.8 | 10.9 | 12.9 | |||

| Proof Load - Fp (N) | |||||||||||

| M3 | 0.50 | 5.03 | 1130 | 1560 | 1410 | 1910 | 2210 | 2920 | 3270 | 4180 | 4880 |

| M3.5 | 0.60 | 6.78 | 1530 | 2100 | 1900 | 2580 | 2980 | 3940 | 4410 | 5630 | 6580 |

| M4 | 0.70 | 8.78 | 1980 | 2770 | 2460 | 3340 | 3860 | 5100 | 5710 | 7290 | 8520 |

| M5 | 0.80 | 14.2 | 3200 | 4400 | 3980 | 5400 | 6250 | 8230 | 9230 | 11800 | 13800 |

| M6 | 1.00 | 20.1 | 4520 | 6230 | 5630 | 7640 | 8840 | 11600 | 13100 | 16700 | 19500 |

| M7 | 1.00 | 28.9 | 6500 | 8920 | 8090 | 11000 | 12700 | 16800 | 18800 | 24000 | 28000 |

| M8 | 1.25 | 36.6 | 8240 | 11400 | 10200 | 13900 | 16100 | 21200 | 23800 | 30400 | 35500 |

| M10 | 1.50 | 58.0 | 13000 | 18000 | 16200 | 22000 | 25500 | 33700 | 37700 | 48100 | 56300 |

| M12 | 1.75 | 84.3 | 19000 | 26100 | 23600 | 32000 | 37100 | 48900d) | 54800 | 70000 | 81800 |

| M14 | 2.00 | 115 | 25900 | 35600 | 32200 | 43700 | 50600 | 66700d) | 74800 | 95500 | 112000 |

| M16 | 2.00 | 157 | 35300 | 48700 | 44000 | 59700 | 69100 | 91000d) | 102000 | 130000 | 152000 |

| M18 | 2.50 | 192 | 43200 | 59500 | 53800 | 73000 | 84500 | 115000 | 159000 | 186000 | |

| M20 | 2.50 | 245 | 55100 | 76000 | 68600 | 93100 | 108000 | 147000 | 203000 | 238000 | |

| M22 | 2.50 | 303 | 68200 | 93900 | 84800 | 115000 | 133000 | 182000 | 252000 | 294000 | |

| M24 | 3.00 | 353 | 79400 | 109000 | 98800 | 134000 | 155000 | 212000 | 293000 | 342000 | |

| M27 | 3.00 | 459 | 103000 | 142000 | 128000 | 174000 | 202000 | 275000 | 381000 | 445000 | |

| M30 | 3.50 | 561 | 126000 | 174000 | 157000 | 213000 | 247000 | 337000 | 466000 | 544000 | |

| M33 | 3.50 | 694 | 156000 | 215000 | 194000 | 264000 | 305000 | 416000 | 570000 | 673000 | |

| M36 | 4.00 | 817 | 184000 | 253000 | 229000 | 310000 | 359000 | 490000 | 678000 | 792000 | |

| M39 | 4.00 | 976 | 220000 | 303000 | 273000 | 371000 | 429000 | 586000 | 810000 | 947000 | |

d) For structural bolting: 50700 N (M12), 68800 N (M14) and 94500 N (M16)

- 1 mm = 0.039 in

- 1 mm2 = 0.00155 in2

- 1 N = 0.1020 kgf = 0.2248 lbf

Metric Bolts - Fine Threads

Minimum Ultimate Tensile Load

For full table with more Property Classes - rotate the screen!

| Thread d (mm) | Pitch P (mm) | Nominal Stress Area As,nom (mm2) | Property Class | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 4.6 | 4.8 | 5.6 | 5.8 | 6.8 | 8.8 | 9.8 | 10.9 | 12.9 | |||

| Minimum Ultimate Tensile Load - Fm,min (N) | |||||||||||

| M8 | 1.00 | 39.2 | 15700 | 16500 | 19600 | 20400 | 23500 | 31360 | 35300 | 40800 | 47800 |

| M10 | 1.25 | 61.2 | 24500 | 25700 | 30600 | 31800 | 36700 | 49000 | 55100 | 63600 | 74700 |

| M10 | 1.00 | 64.5 | 25800 | 27100 | 32300 | 33500 | 38700 | 51600 | 58100 | 67100 | 78700 |

| M12 | 1.50 | 88.1 | 35200 | 37000 | 44100 | 45800 | 52900 | 70500 | 79300 | 91600 | 107000 |

| M12 | 1.25 | 92.1 | 36800 | 38700 | 46100 | 47900 | 55300 | 73700 | 82900 | 95800 | 112000 |

| M14 | 1.50 | 125 | 50000 | 52500 | 62500 | 65000 | 75000 | 100000 | 112000 | 130000 | 152000 |

| M16 | 1.50 | 167 | 66800 | 70100 | 83500 | 86800 | 100000 | 134000 | 150000 | 174000 | 204000 |

| M18 | 1.50 | 216 | 86400 | 90700 | 108000 | 112000 | 130000 | 179000 | 225000 | 264000 | |

| M20 | 1.50 | 272 | 109000 | 114000 | 136000 | 141000 | 163000 | 226000 | 283000 | 332000 | |

| M22 | 1.50 | 333 | 133000 | 140000 | 166000 | 173000 | 200000 | 276000 | 346000 | 406000 | |

| M24 | 2.00 | 384 | 154000 | 161000 | 192000 | 200000 | 230000 | 319000 | 399000 | 469000 | |

| M27 | 2.00 | 496 | 198000 | 208000 | 248000 | 258000 | 298000 | 412000 | 516000 | 605000 | |

| M30 | 2.00 | 621 | 248000 | 261000 | 310000 | 323000 | 373000 | 515000 | 646000 | 758000 | |

| M33 | 2.00 | 761 | 304000 | 320000 | 380000 | 396000 | 457000 | 632000 | 791000 | 928000 | |

| M36 | 3.00 | 865 | 346000 | 363000 | 432000 | 450000 | 519000 | 718000 | 900000 | 1055000 | |

| M39 | 3.00 | 1030 | 412000 | 433000 | 515000 | 536000 | 618000 | 855000 | 1070000 | 1260000 | |

Proof Load

For full table with more Property Classes - rotate the screen!

| Thread d (mm) | Pitch P (mm) | Nominal Stress Area As,nom (mm2) | Property Class | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 4.6 | 4.8 | 5.6 | 5.8 | 6.8 | 8.8 | 9.8 | 10.9 | 12.9 | |||

| Proof Load - Fp (N) | |||||||||||

| M8 | 1.00 | 39.2 | 8820 | 12200 | 11000 | 14900 | 17200 | 22700 | 25500 | 32500 | 38000 |

| M10 | 1.25 | 61.2 | 13800 | 19000 | 17100 | 23300 | 26900 | 33500 | 39800 | 50800 | 59400 |

| M10 | 1.00 | 64.5 | 14500 | 20000 | 18100 | 24500 | 28400 | 37400 | 41900 | 53500 | 62700 |

| M12 | 1.50 | 88.1 | 19800 | 27300 | 24700 | 33500 | 38800 | 51100 | 57300 | 73100 | 85500 |

| M12 | 1.25 | 92.1 | 20700 | 28600 | 25800 | 35000 | 40500 | 53400 | 59900 | 76300 | 89300 |

| M14 | 1.50 | 125 | 28100 | 38800 | 35000 | 47500 | 55000 | 72500 | 81200 | 104000 | 121000 |

| M16 | 1.50 | 167 | 27600 | 51800 | 46800 | 63500 | 73500 | 96900 | 109000 | 139000 | 162000 |

| M18 | 1.50 | 216 | 48600 | 67000 | 60500 | 82100 | 95000 | 130000 | 179000 | 210000 | |

| M20 | 1.50 | 272 | 61200 | 84300 | 76200 | 103000 | 120000 | 163000 | 226000 | 264000 | |

| M22 | 1.50 | 333 | 74900 | 103000 | 93200 | 126000 | 146000 | 200000 | 276000 | 323000 | |

| M24 | 2.00 | 384 | 86400 | 119000 | 108000 | 146000 | 169000 | 230000 | 319000 | 372000 | |

| M27 | 2.00 | 496 | 112000 | 154000 | 139000 | 188000 | 218000 | 298000 | 412000 | 481000 | |

| M30 | 2.00 | 621 | 140000 | 192000 | 171000 | 236000 | 273000 | 373000 | 515000 | 602000 | |

| M33 | 2.00 | 761 | 171000 | 236000 | 213000 | 289000 | 335000 | 457000 | 632000 | 738000 | |

| M36 | 3.00 | 865 | 195000 | 268000 | 242000 | 329000 | 381000 | 519000 | 718000 | 838000 | |

| M39 | 3.00 | 1030 | 232000 | 319000 | 288000 | 391000 | 453000 | 618000 | Proof Load | 855000 | 999000 |

Ultimate Tensile and Proof loads for metric bolts according ISO 898-1 "Mechanical properties of fasteners made of carbon steel and alloy steel - Part 1: Bolts, screws and studs with specified property classes — Coarse thread and fine pitch thread".