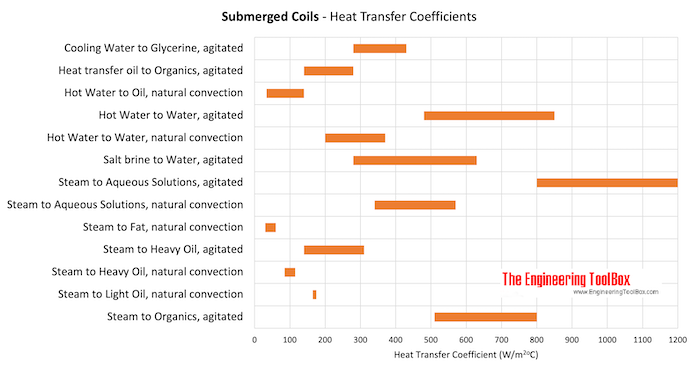

Submerged Coils - Heat Transfer Coefficients

Heat transfer coefficients for steam and hot water coils submerged in oil tanks.

The overall heat transfer coefficients for steam coils with medium pressure - or hot water coils or pipes - submerged in oil or fat:

| Type of Coil | Heat Transfer Coefficient - U - | |

|---|---|---|

| (W/m2 oC) | (Btu/hr ft2 oF) | |

| Steam to Aqueous Solutions, agitated | 800 - 1200 | 140 - 210 |

| Steam to Aqueous Solutions, natural convection | 340 - 570 | 60 - 100 |

| Steam to Light Oil, natural convection | 170 | 30 |

| Steam to Heavy Oil, natural convection | 85 - 115 | 15 - 20 |

| Steam to Heavy Oil, agitated | 140 - 310 | 25 - 55 |

| Steam to Fat, natural convection | 30 - 60 | 5 - 10 |

| Steam to Organics, agitated | 510 - 800 | 90 - 140 |

| Hot Water to Oil, natural convection | 34 - 140 | 6 - 25 |

| Hot Water to Water, natural convection | 200 - 370 | 35 - 65 |

| Hot Water to Water, agitated | 480 - 850 | 90 - 150 |

| Heat transfer oil to Organics, agitated | 140 - 280 | 25 - 50 |

| Salt brine to Water, agitated | 280 - 630 | 50 - 110 |

| Cooling Water to Glycerine, agitated | 280 - 430 | 50 - 75 |

Example - Heat Transfer from a Steam Coil

A 50 mm steam coil with outside diameter 60.3 mm(0.0603 m) and length 10 m with 1 bar absolute pressure and steam temperature 120 oC is submerged in an oil bath with temperature 50 oC.

The surface area of the coil can be calculated by multiplying the pipe circumference with pipe length as

A = π (0.0603 m) (10 m)

= 1.89 m2

From the table above the heat transfer coefficient is 170 W/m2 oC for "Steam to Light Oil, Natural Convection". The heat transfer can be calculated as

Q = (1.89 m2)((120 oC) - (50 oC))(170 W/m2 oC)

= 22491 W