High Pressure Steam Systems - Safety Valve Capacities

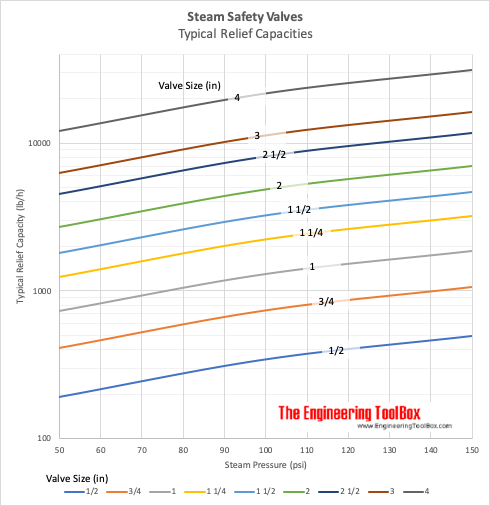

Sizing safety valves according boiler output power in high pressure systems (kW and Btu/hr)

The main purpose for a safety valve is

- to prevent the pressure in a system to exceed certification pressure

Above certification pressure no one can guaranty the systems safety - and especially for a steam system with a very hot gas with a huge amount of latent heat the consequence with a failure can be dramatically.

The size of a safety valve depends primarily on the maximum boiler output and the operation pressure of the system. The safety valve must as minimum have the evacuation capacity of all the vapor the boiler can produce running at full power at the working (or certification) pressure.

- for a higher pressure the steam is compressed and requires less volume and the size of the valve can be reduced

- for a lower pressure the steam is expanded and requires more volume and the size of the valve is increased

The tables below can be used to select a typical safety valve in a high pressure system. Before the final design - always consult manufacturing documentation.

Steam Pressure 1000 kPa (10 bar) and 150 psi

| Pipe Size | Capacity | Maximum Boiler Output | |||

|---|---|---|---|---|---|

| in | DN (mm) | kg/h | lb/h | kW | Btu/h |

| 1/2 | 15 | 220 | 498 | 122 | 426 786 |

| 3/4 | 20 | 472 | 1 070 | 262 | 916 990 |

| 1 | 25 | 827 | 1 875 | 459 | 1 606 875 |

| 1 1/4 | 32 | 1 421 | 3 222 | 789 | 2 761 254 |

| 1 1/2 | 40 | 2 058 | 4 668 | 1 143 | 4 000 476 |

| 2 | 50 | 3 065 | 6 954 | 1 702 | 5 959 578 |

| 2 1/2 | 65 | 5 144 | 11 670 | 2 856 | 10 001 190 |

| 3 | 80 | 7 108 | 16 124 | 3 947 | 13 818 268 |

| 4 | 100 | 13 694 | 31 067 | 7 604 | 26 624 419 |

Note! The table above is based on steam with pressure 1000 kPa (10 bar) (or 150 psi in imperial units). Latent heat of saturated steam is 1999 kJ/kg (857 Btu/lb).

Steam Pressure 700 kPa (7 bar) and 100 psi

| Pipe Size | Capacity | Maximum Boiler Output | |||

|---|---|---|---|---|---|

| in | DN (mm) | kg/h | lb/h | kW | Btu/h |

| 1/2 | 15 | 159 | 346 | 90 | 304 480 |

| 3/4 | 20 | 342 | 743 | 194 | 653 840 |

| 1 | 25 | 599 | 1 302 | 340 | 1 145 760 |

| 1 1/4 | 32 | 1 030 | 2 238 | 585 | 1 969 440 |

| 1 1/2 | 40 | 1 792 | 3 242 | 1 018 | 2 852 960 |

| 2 | 50 | 2 222 | 4 827 | 1 263 | 4 247 760 |

| 2 1/2 | 65 | 3 730 | 8 101 | 2 120 | 7 128 880 |

| 3 | 80 | 5 153 | 11 193 | 2 929 | 9 849 840 |

| 4 | 100 | 9 929 | 21 566 | 5 643 | 18 978 080 |

Note! The table above is based on steam with pressure 700 kPa (7 bar) (or 100 psi in imperial units). Latent heat of saturated steam is 2046 kJ/kg (880 Btu/lb).

Steam Pressure 300 kPa (3 bar) and 50 psi

| Pipe Size | Capacity | Maximum Boiler Output | |||

|---|---|---|---|---|---|

| in | DN (mm) | kg/h | lb/h | kW | Btu/h |

| 1/2 | 15 | 79 | 193 | 47 | 176 016 |

| 3/4 | 20 | 169 | 414 | 100 | 377 568 |

| 1 | 25 | 296 | 726 | 175 | 662 112 |

| 1 1/4 | 32 | 509 | 1 248 | 302 | 1 138 176 |

| 1 1/2 | 40 | 737 | 1 807 | 437 | 1 647 984 |

| 2 | 50 | 1 099 | 2 695 | 651 | 2 457 840 |

| 2 1/2 | 65 | 1 844 | 4 522 | 1 093 | 4 124 064 |

| 3 | 80 | 2 547 | 6 248 | 1 509 | 5 698 176 |

| 4 | 100 | 4 907 | 12 038 | 2 907 | 10 978 656 |

Note! The table above is based on steam with pressure 300 kPa (3 bar) (or 50 psi in imperial units). Latent heat of saturated steam is 2133 kJ/kg (912 Btu/lb).

- 1 N/m2 = 1 Pa = 1.4504×10-4 lb/in2 (psi) = 1×10-5 bar