Bimetallic Strips

Heat and bending of bimetallic strips.

Bi-metallic strips are subject to bending due to heat - and can be used to convert change in temperature to mechanical displacement.

Bending occurs towards the side of the metal with the lowest temperature coefficient of expansion.

Bi-metal strips

- consists of two strips of different metals with different temperature expansion coefficients

- are usually made with steel (12×10-6 K-1) and copper (16.6×10-6 K-1) (or brass 18.7×10-6 K-1) joined together (often welded) throughout the length

- are typically used in thermostats

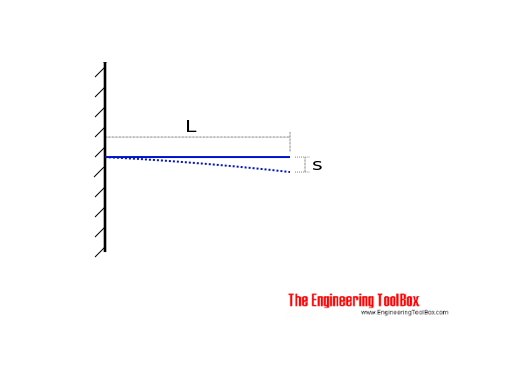

Assuming two metals with the same shape joined together - bending of a bi-metal strip due to change in the temperature can be calculated as

s = α L2 dt / t (1)

where

s = bending (m)

α = 13 - 19×10-6 K-1 (typical aprox. 14×10-6 K-1 - check manufacturers catalogs and specifications)

L = length of bimetallic strip (m)

dt = temperature difference (oC)

t = thickness of bimetallic strip (m)

Example - Bending of Bi-metal strip

A bi-metal strip with α = 14×10-6 K-1, length 50 mm and thickness 2 mm is heated 100 oC. The bending can be calculated as

s = (14×10-6 K-1) ((50 mm) 1/1000 m/mm)2 (100 oC) / ((2 mm) (1/1000 m/mm))

= 0.00175 m

= 1.75 mm