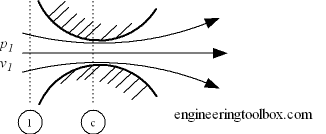

Nozzles

Gas flow through nozzles and sonic chokes.

The maximum gas flow through a nozzle is determined by critical pressure.

- critical pressure ratio is the pressure ratio where the flow is accelerated to a velocity equal to the local velocity of sound in the fluid

Critical flow nozzles are also called sonic chokes. By establishing a shock wave the sonic choke establish a fixed flow rate unaffected by the differential pressure, any fluctuations or changes in downstream pressure. A sonic choke may provide a simple way to regulate a gas flow.

The ratio between critical pressure and initial pressure for a nozzle can expressed as

pc / p1 = (2 / (n + 1))n / (n - 1) (1)

where

pc = critical pressure (Pa)

p1 = inlet pressure (Pa)

n = index of isentropic expansion or compression - or polytropic constant

For a perfect gas undergoing an adiabatic process the index - n - is the ratio of specific heats - k = cp / cv. There is no unique value for - n. Values for some common gases

- Steam where most of the process occurs in the wet region : n = 1.135

- Steam superheated : n = 1.30

- Air : n = 1.4

- Methane : n = 1.31

- Helium : n = 1.667

Example - Air Nozzles and Critical Pressure Ratios

The critical pressure ratio for an air nozzle can be calculated as

pc / p1 = (2 / (1.4 + 1))1.4 / (1.4 - 1)

= 0.528

Critical pressures for other values of - n:

| n | 1.135 | 1.300 | 1.400 | 1.667 |

| pc/ p1 | 0.577 | 0.546 | 0.528 | 0.487 |

Mass Flow through Nozzles

The mass flow through a nozzle with sonic flow where the minimum pressure equals the critical pressure can be expressed as

mc = Ac (n p1 ρ1)1/2 (2 / (n + 1))(n + 1) / 2(n - 1) (2)

where

mc = mass flow at sonic flow (kg/s)

Ac = nozzle area (m2)

ρ1 = initial density (kg/m3)