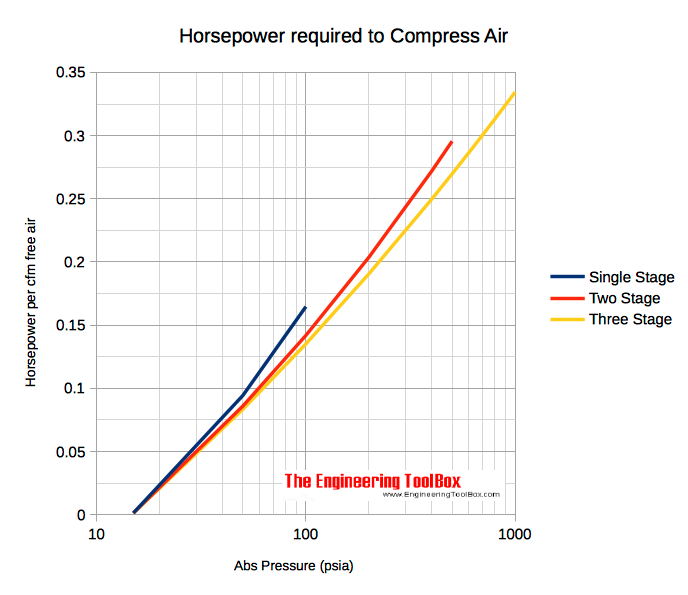

Horsepower required to Compress Air

Calculate horsepower required by air compressors.

The horsepower required to adiabatic compression of air can be calculated with the calculator below:

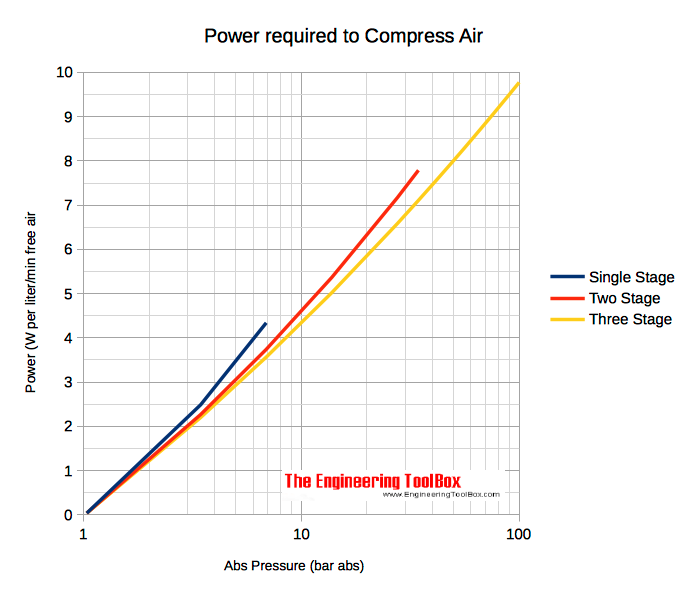

Theoretical horsepower required to compress one cubic foot of free air (atmospheric pressure) for single-staged, two-staged and three-staged compressors are indicated in the diagram below. In general - plus 15-20% friction.

- 1 cfm (ft3/min) = 1.7 m3/h = 0.47 l/s = 28.3 l/min

- 1 psi (lb/in2) = 6894.8 Pa (N/m2) = 6.895×10-2 bar

- 1 hp = 745.7 W

The power required for adiabatic (process without transfer of heat) compression of air can be expressed as

HP = (144 N P1 V k / (33000 (k - 1))) ((P2 / P1)(k - 1) / (N k) - 1) (1)

where

HP = horsepower

N = number of compression stages

k = 1.41 = adiabatic expansion coefficient

P1 = absolute initial atmospheric pressure (psi) (14.7 psi at sea level)

P2= absolute final pressure after compression (psi)

V = volume of air at atmospheric pressure - standard or free air (scfm, ft3/min)

- adiabatic compression (or expansion) takes place without transmission of heat